Accessories – Uniguard Security Screen

Universal Window and Door provides a variety of accessories to complement our award-winning historic and custom windows. We offer a wide selection of stock awnings, grids, screens, pannings and trim or we can custom manufacture items to accommodate the needs of our valued customers.

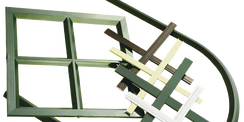

Universal Internal and External Grids and Muntins are specially designed to coordinate with all Universal window designs and are custom-manufactured to meet your specifications for historic, architectural, and aesthetic requirements. And Universal grids are compatible with many manufacturers.

Universal specializes in building grid layouts and systems to serve your architectural and historical building needs. Give us a drawing, picture or sample of your project to replicate your customer’s desired grid patterns and profiles. Universal also provides UNIGUARD vandal-resistant and child guard screens.

Product Features

| Performance | • Painted stainless steel mesh • .023 Stainless Steel 12x12 mesh doubles as insect/impact screen • 1/2” 90 degree bend on screen mesh provides greater impact resistance • Extra strong double hollow aluminum frame • Factory applied paint finish on frame is maintenance-free • “Step-Frame” allows installation in existing screen tracks • Adjustable tension screws assure a secure fit of screen to window frame " |

| Options | |

| Specifications | General: The Child Guard or Vandal-Resistant Screen is designed to provide a reasonable degree of impact resistance from both inside and outside. Universal Window and Door makes no express declaration of “degree of security” these screens provide. Material: The aluminum is of commercial quality 6063-T5 alloy with a minimum tensile strength of 22,000 psi, free from any defects imparing strength and durability, and with standard wall thickness tolerances as defined in the Architectural Aluminum Manufacturers Association Master Specification. Construction: Double hollow frames are mitered and mechanically fastened utilizing one set (4) of die cast corner keys, and one set (4) of stamped aluminum corner keys. The mesh is bent at 90 degrees, and secured to the frame by a multi-screwed continuous retainer bracket. Full screen tie-bar is attached to the screen frame with four concealed L-brackets screwed to both tie-bar and frame. Installation: Screens MUST be properly secured to surrounding window or other wall application. The jamb tension screws on the screen frame and/or other optional latches must be properly adjusted to assure that the screen is secure in the screen track or other surround. The screen is only as strong as the surrounding frame in which it is installed. Finish: The exposed surfaces of all aluminum members are provided clean and free of surface blemishes. Standard finishes are bronze, white, ivory, black or green electrostatically applied baked acrylic enamel, with a 5-stage chromate undercoating conforming to AAMA 603. standards. Other architect specified finishes may be available at additional cost. Weather-stripping: Stripping is dense, open cell foam tape at the meeting rail of half screens to act as a bug seal. Performance: Our screens meet the 60 day salt spray test per ASTM b-117. Screen wire meets 100 ft lb impact test which is equivalent to “heavy type” HUD security screen specifications. Hardware: All fasteners, screws and other miscellaneous fastening devices are of non-corrosive material compatible with aluminum. Standard screens are removable by compression of two (2) side springs, and are equipped with four (4) Allen or Phillips head type adjustable tension screws. |